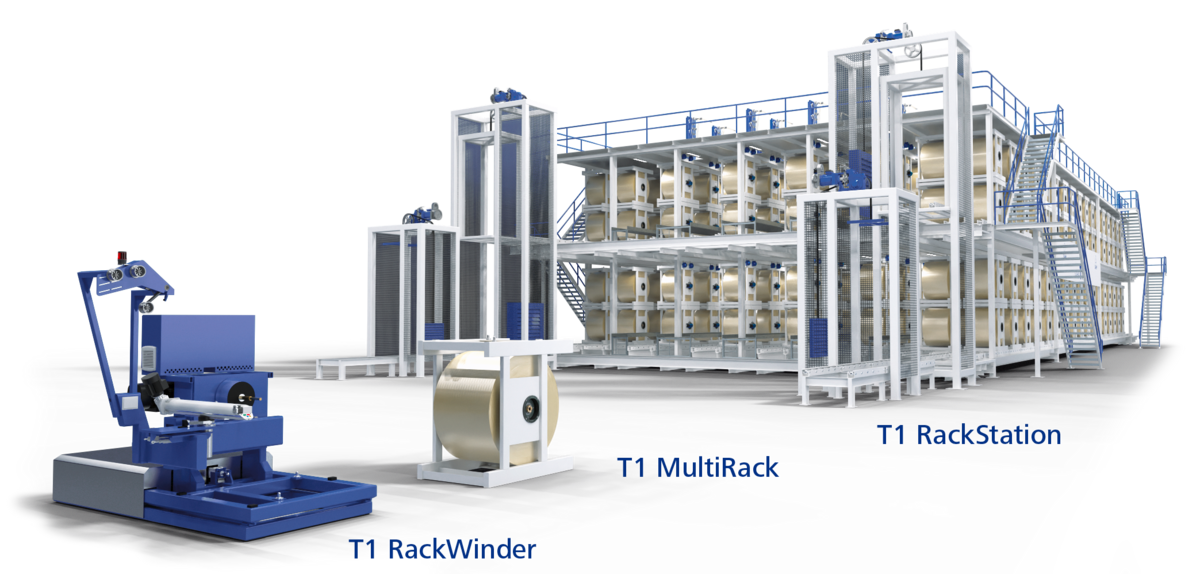

SAHM T1 System

Rethinking Carbon Fiber Manufacturing.

The revolutionary SAHM T1 system, based on technology from the world’s leading provider of winding technology, is a completely new concept for handling materials in upstream carbon fiber processes. The system uses bobbins with one ton or more of PAN precursor material. This extra-large format results in significantly fewer oven stops, making it possible to achieve a tripling of production output while also reducing waste. And all with a remarkably speedy return on investment.

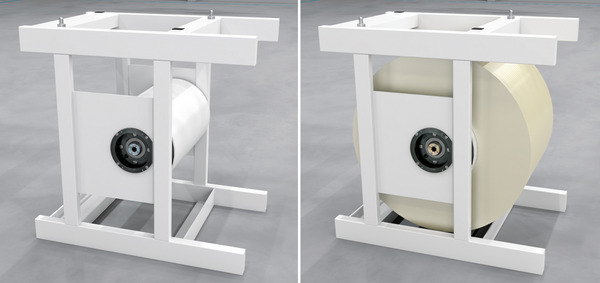

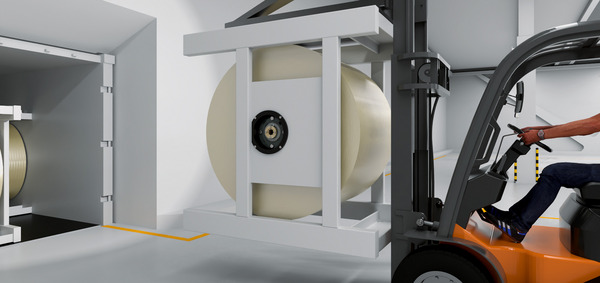

The robust steel frame of the T1 MultiRack safely protects the sensitive PAN precursor material during transport and storage.

Simply stacked on top of each other, T1 MultiRacks replace inconvenient shelving systems.

The anchoring system integrated in the frame allows safe stacking of up to three racks and also facilitates easy transport.

The revolutionary SAHM T1 system works with the technology from the world’s leading provider of winding technology. It can bring exceptional benefits to your production:

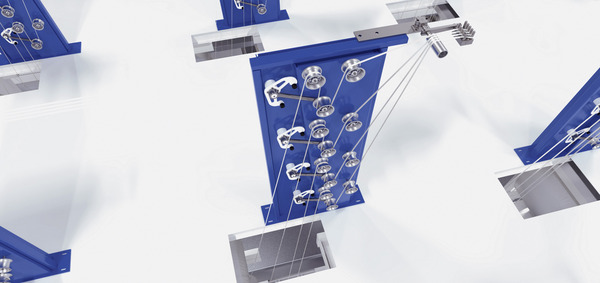

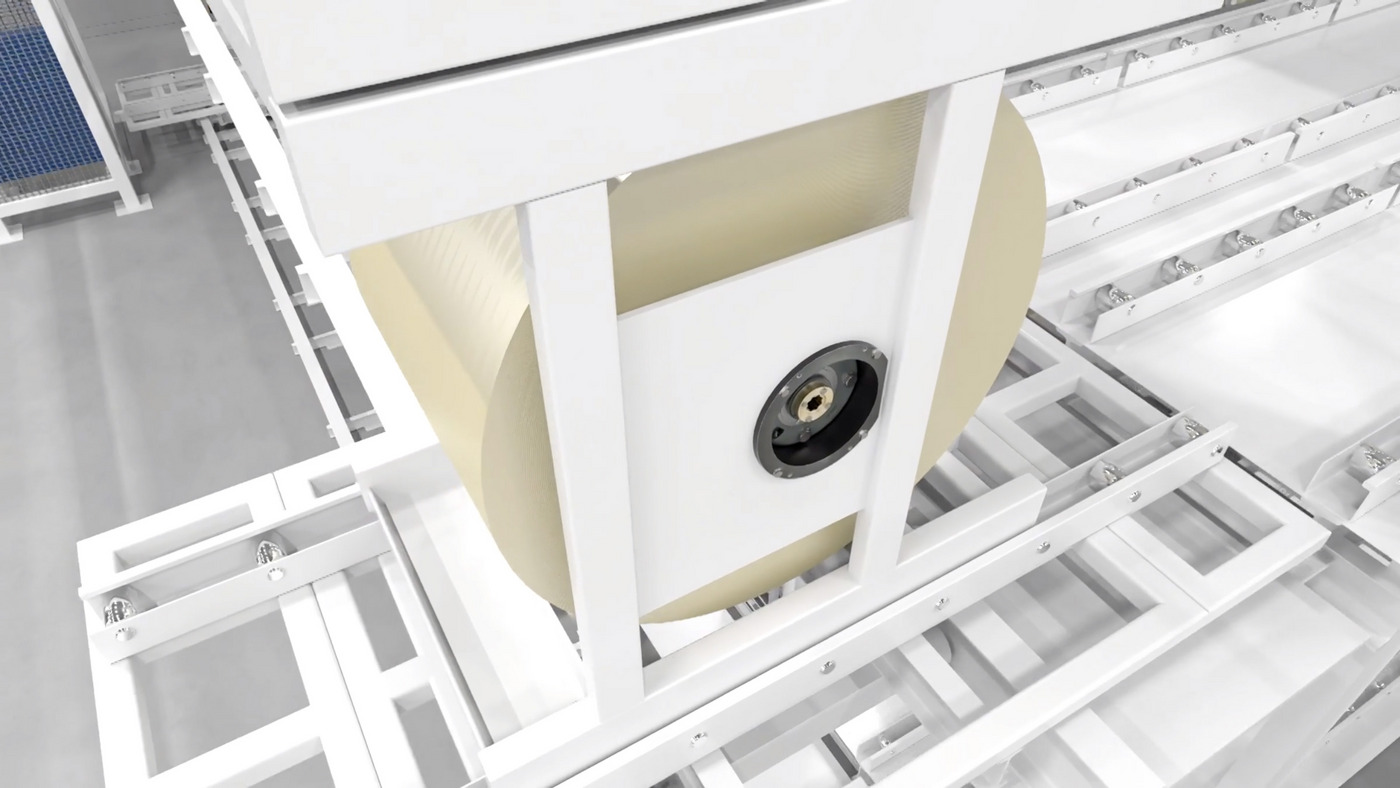

SAHM T1 RackWinder. The game changer.

The T1 RackWinder precisely crosswinds sensitive PAN precursor material into stable one-ton bobbins. With speeds of up to 600 m/min and an electronically controlled winding ratio, the T1 RackWinder is suitable for both wet spinning and air-gap spinning processes. Its configuration can be customized according to customer requirements and spinning technology.

Contact